KRN undertakes Green field Projects on Consultancy / Turnkey Basis, provides Design, Details Engineering, Technical, Management, Training, Recruitment and Erection & Installation services to Steel Industry for the manufacturing of Sponge Iron, Hot Briquette Iron (HBI), Steel Billets/ Ingots, Rolling Mills, ERW Pipes, Powder Metallurgy, Sintering Units, Welding Units.

KRN is specialized in Erection, Installation manufacturing of subsequent equipment of Induction Furnace, Continuous Casting Machines (CCM) and other Auxiliary Equipments of Steel making.

Sed ut perspiciatis undeomnis iste natus error sit voluptatem accusantium dolore Totam rem aperiam with a long list of products and never ending customer support.

Turnkey supply of Steel melting shop, Continuous Casting Plant & Re - Rolling Mills (Brought out items to be directly purchased by Party with consultation and support by us)

Supervision of Construction, erection and commissioning.

We undertake Erection & Installation of Steel Melting Shop equipments i.e. Induction Furnace from small capacity (3 MT) to very large capacity (40 MT), Continuous Casting Machine upto 6/11 Radius - 2 /3 strands, BOF, LRF, EOT cranes, FES, Duct Cleaning System, Cooling Tower, AOD, LT / HT sub station and utilities at most economic terms.

We also provide recruitment services to our clients across the world for their steel melting shops. All the Manpower supplied by us are highly experienced and have hands on experience of working with most reputed Steel plants.

Continuous Casting is the process whereby molten steel is solidified into a "semi finished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of Continuous Casting in the 1950s, steel was poured into stationary molds to form "ingots". Since then, "continuous casting" has evolved to achieve improved yield, quality, productivity and cost efficiency.

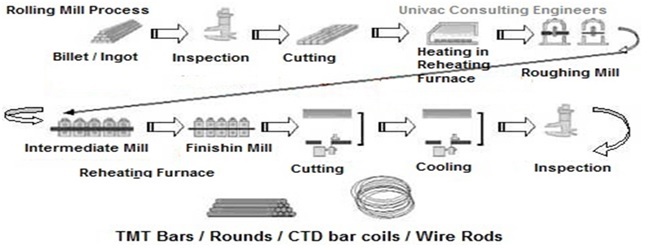

This is a special heat-treatment process,wherein the heat treatment is from the rolling process itself. At the exit of the rolled product,the ribbed bar is subjected to the TMT process,which involves 3 stages.